NetSuite ERP Software for Manufacturing Companies

Scale and grow your Manufacturing & Distribution Business

The Best Software for Manufacturing Companies

Transform Your Manufacturing Business with Software Built for the Cloud

Build, run, and grow your manufacturing business on NetSuite

Improve Productivity and Reduce Operational cost with automations for Manufacturing

Manufacturing Companies can digitalise their business and automate processes around customer service easily with NetSuite ERP Software

Organisations can create significant improvements with ERP deployment.

➤ Complete Inventory Control

➤ Link All the Departments of a Manufacturing Company

➤ Automate Work Order Management & Production Scheduling

➤ Streamline Supply Chain & Order Fulfillment Process

➤ Provide Accurate Data & Improve Decision-Making

The Bottom Line:

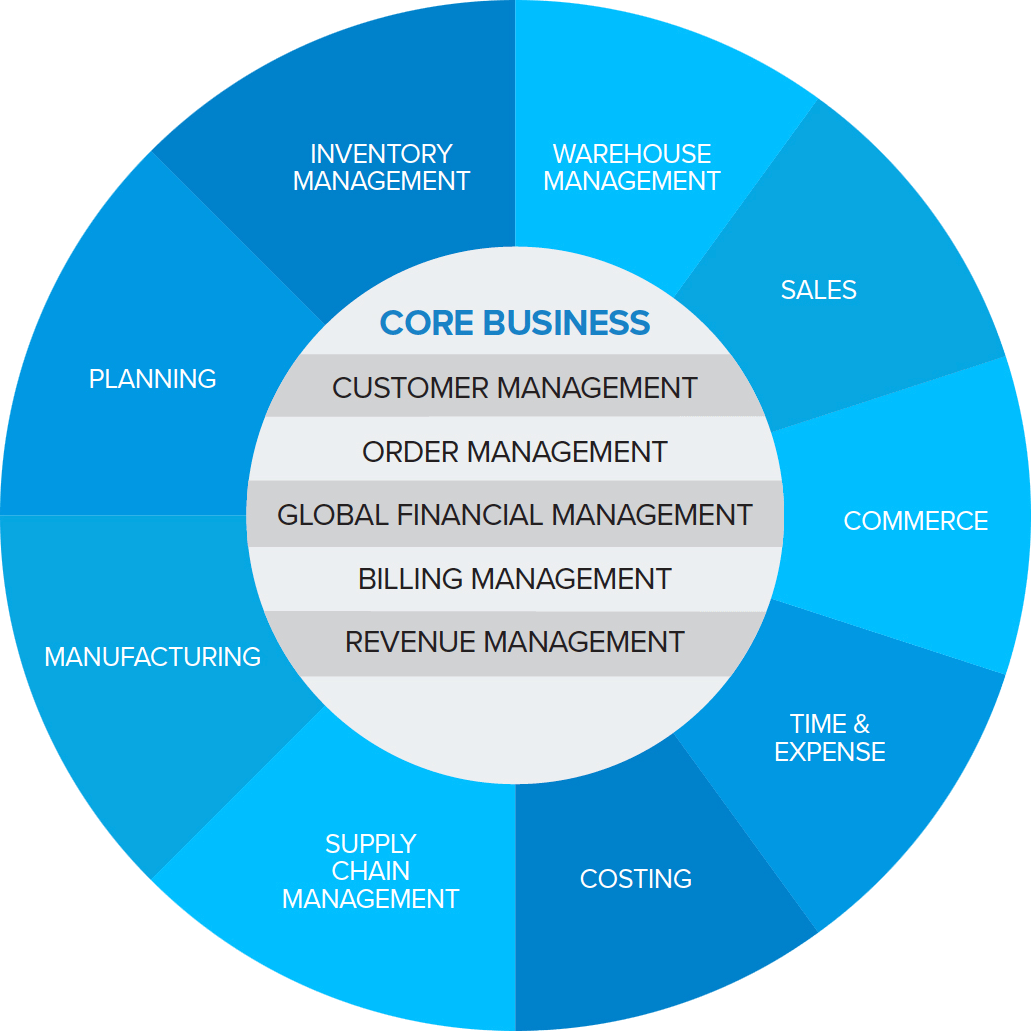

NetSuite provides a full business solution for manufacturers.

Complete Business Solutions

NetSuite Software for Manufacturing Companies Features & Benefits

CRM

Elevate Customer Relationships with NetSuite’s CRM – Manage interactions, foster loyalty, and create exceptional customer experiences.

PRODUCT DATA MANAGEMENT

Streamline Design with NetSuite’s Product Data Management – Centralise data, expedite product launches, and reduce time to market.

ORDER MANAGEMENT

Boost Sales Confidence with NetSuite’s Order Management – Ensure accurate orders, optimal pricing, and efficient fulfilment.

PLANNING AND SCHEDULING

Achieve Inventory Excellence with NetSuite’s Planning and Scheduling – Balance demand and supply for timely inventory placement.

PROCUREMENT

Optimise Procurement Efficiency with NetSuite – Vendor management and price optimisation for cost-effective purchasing.

PRODUCTION CONTROL

NetSuite’s Production Control: Seamlessly Manage Work Orders – From creation to monitoring, ensure efficient production.

SUPPLY CHAIN

Strengthen Your Supply Chain with NetSuite – Collaborate seamlessly, optimise workflows, and enhance your entire supply chain.

SHOP FLOOR CONTROL

Extend Control with NetSuite’s Shop Floor Management – Monitor outsourced manufacturing as easily as internal processes.

QUALITY MANAGEMENT

Ensure Quality Excellence with NetSuite – Define inspection criteria, real-time monitoring, and actionable insights.

NetSuite provides a full business solution for Manufacturing Companies

Evolve Your Manufacturing Business

With NetSuite’s true-cloud application and AVT’s expertise, you can run your entire manufacturing business from end-to-end as a fully integrated Planning, Financials, Inventory Management, Production Scheduling and CRM solution. Take advantage of having one system to manage inventory and financials as well as enabling sales presence expansion through an integrated platform, anytime, anywhere.

The #1 Cloud Business Software

NetSuite Isn’t Just for Startups

Manufacturing companies of all sizes could profit from improved visibility and increased efficiency. NetSuite offers these benefits with its comprehensive, global financial and accounting core. As your business grows and evolves, scale your organisation by eliminating costly and inefficient manual processes and disparate systems.

Startups, midsize, and enterprise manufacturing providers all benefit from NetSuite’s award-winning solutions. Today, over 24,000 companies trust NetSuite to provide the foundation to operate their business processes.

Dynamic and forward-looking, NetSuite provides real-time data insights to allow you to make important path adjustments & project changes for global expansion success.

NetSuite is the scalable foundation for high-growth technology companies. Trust the solution powering today’s fastest-growing companies — from startup to IPO and beyond.

Don’t allow growth of your company to translate to complexity. Let NetSuite automate and unite your key business processes for increased financial efficiency and accuracy.

Easy to use and always accessible, NetSuite is the solution that fosters innovation within your organization.

A Pathway to Success

Leading Practices for Wholesale Distribution Companies

• Run your entire business on a single, true cloud platform. Rid yourself of multiple, disparate applications and bring all your data into a single, customizable system, accessible from anywhere.

• Know your operations like never before. Gain insight from data gathered across your organization and empower your employees with the information they need.

• Get a 360-degree view of your customers. Record every interaction automatically in a single, searchable system—from marketing to selling to service and support.

• Engage users everywhere with omnichannel commerce. Reach your customers online,

by phone, over email, in person and more. Exceed the evolving expectations of 21st century consumers.

by phone, over email, in person and more. Exceed the evolving expectations of 21st century consumers.

NetSuite Module Data Sheets

AVT Manufacturing Customers

ERP Case Studies

With over 15 years of experience and 1000+ business improvement projects, we are proud to have transformed the processes and systems of many businesses, both locally and globally.

We help companies get ahead of the competition

We help companies get ahead

of the competition

of the competition

Australia’s Leading NetSuite Partner & Solution Provider

Over 15 years of success with 1000+ business & process improvements

Focused on Services, Wholesale, Distribution & Manufacturing verticals, we deliver effective and simplified processes through NetSuite Cloud ERP, helping you to make faster and better decisions.

FREQUENTLY ASKED QUESTIONS

Maximise Your NetSuite Investment with the Experts Support

What is Manufacturing ERP software?

Manufacturing ERP (Enterprise Resource Planning) software is a specialised solution designed to meet the unique requirements of manufacturing companies. It serves as a comprehensive platform that integrates and optimises various aspects of manufacturing operations, resource management, supply chain, and financials. By centralising data and processes, manufacturing ERP software enhances efficiency, facilitates informed decision-making, and supports the entire production lifecycle.

At its core, Manufacturing ERP software works by providing a centralised hub for managing the intricate processes within a manufacturing environment. Here’s an overview of how it operates:

- Production Planning: Manufacturing ERP software assists in creating production plans based on factors like demand forecasts, current inventory levels, and order backlogs. It helps optimise resource allocation and scheduling to ensure timely and cost-effective production.

- Inventory Management: The software tracks raw materials, work-in-progress, and finished goods across multiple locations. It ensures accurate inventory levels, minimises overstocking or stock-outs, and streamlines reorder processes.

- Shop Floor Control: Manufacturing ERP offers tools to monitor and manage activities on the shop floor. It provides real-time visibility into work orders, progress tracking, and production status updates.

- Quality Control: The software supports quality management by enabling businesses to define quality standards, conduct inspections, and manage non-conformances. This ensures that products meet or exceed customer expectations.

- Supply Chain Management: Manufacturing ERP software integrates with suppliers, distributors, and logistics partners. It facilitates procurement, tracks shipments, and optimises the supply chain for efficiency.

- Demand Forecasting: By analysing historical data and market trends, the software helps manufacturers forecast demand accurately. This assists in aligning production with customer needs.

- Resource Optimisation: Manufacturing ERP allocates resources, such as labour, machinery, and materials, efficiently. It minimises wastage, reduces production costs, and enhances overall productivity.

- Financial Management: The software handles financial aspects like cost tracking, budgeting, and reporting. It ensures accurate financial visibility across manufacturing operations.

- Real-Time Reporting and Analytics: Manufacturing ERP provides customisable dashboards and reports, offering insights into key performance indicators (KPIs) like production efficiency, resource utilisation, and profitability.

- Regulatory Compliance: Manufacturing ERP software assists in adhering to industry regulations and compliance standards by providing tools for documentation and reporting.

In essence, Manufacturing ERP software streamlines complex manufacturing processes, fosters collaboration, and empowers manufacturers to make informed decisions. It unifies different departments within a manufacturing company, promoting efficiency, quality, and innovation across the entire value chain. NetSuite’s Manufacturing ERP solution offers these capabilities, tailored specifically for manufacturing businesses, to drive growth, adaptability, and success in a competitive manufacturing landscape.

Is NetSuite good for manufacturing?

Yes, NetSuite is highly regarded as a comprehensive and effective solution for manufacturing companies. It offers a specialised Manufacturing ERP (Enterprise Resource Planning) module that caters to the unique needs and challenges of manufacturing operations. NetSuite’s Manufacturing ERP provides a wide range of features and capabilities that make it a suitable choice for manufacturing companies looking to streamline their processes, improve efficiency, and achieve operational excellence.

Here’s why NetSuite is considered good for manufacturing:

- Industry-Specific Functionality: NetSuite’s Manufacturing ERP module is designed with manufacturing processes in mind. It includes features for production planning, shop floor control, inventory management, quality control, and more, tailored to meet the requirements of various manufacturing industries.

- End-to-End Integration: NetSuite integrates various aspects of manufacturing operations, including production, inventory, supply chain, financials, and more, into a single platform. This integration enhances visibility, eliminates data silos, and facilitates seamless collaboration.

- Real-Time Visibility: NetSuite provides real-time insights into key performance indicators (KPIs) such as production efficiency, resource utilisation, and inventory levels. This enables manufacturers to make informed decisions and quickly respond to changing market conditions.

- Advanced Planning Tools: NetSuite’s Manufacturing ERP offers advanced planning and scheduling tools to optimise production processes, allocate resources effectively, and ensure on-time deliveries.

- Quality Management: The software supports quality control and assurance by enabling manufacturers to define quality standards, conduct inspections, and manage non-conformances, ensuring product quality and customer satisfaction.

- Supply Chain Optimisation: NetSuite facilitates end-to-end supply chain management by integrating suppliers, distributors, and logistics partners. This streamlines procurement, reduces lead times, and enhances overall supply chain efficiency.

- Customisation and Flexibility: NetSuite’s customisable workflows and configurations allow manufacturers to adapt the software to their unique processes and requirements. This ensures that the software aligns with the way their business operates.

- Scalability: NetSuite can grow with your manufacturing business. Whether you’re a small manufacturer or a large enterprise, NetSuite offers scalability to accommodate changing production volumes and business expansion.

- Cloud-Based Solution: NetSuite is a cloud-based solution, which means it offers accessibility from anywhere, easy updates, and reduced IT overhead. This is particularly beneficial for manufacturers with multiple locations or remote teams.

- Industry Expertise: NetSuite has a track record of success in serving manufacturing companies across various industries, including discrete manufacturing, process manufacturing, electronics, automotive, and more.

In summary, NetSuite’s Manufacturing ERP software is well-suited for manufacturing companies seeking to streamline their operations, improve efficiency, and gain a competitive edge in their industry. It offers industry-specific functionality, end-to-end integration, and real-time visibility to support manufacturers in achieving their business goals and driving growth. At AVT, Australia’s Leading NetSuite Solution Provider, we’re committed to helping Manufacturing businesses harness NetSuite’s full potential to drive growth, efficiency, and success in a highly competitive market.

Is NetSuite a CRM made for Manufacturing?

While NetSuite is primarily known as an Enterprise Resource Planning (ERP) solution, it does include Customer Relationship Management (CRM) capabilities as well. These CRM functionalities are designed to support various industries, including manufacturing. However, NetSuite’s CRM features are not exclusively tailored only for manufacturing; they are intended to address the needs of businesses across different sectors, including manufacturing companies.

NetSuite’s CRM capabilities provide tools to manage customer interactions, sales processes, lead management, and customer service. This can be beneficial for manufacturing companies that want to enhance customer relationships, manage sales activities, and provide efficient customer support.

Some of the CRM features that NetSuite offers and that can benefit manufacturing businesses include:

- Lead and Opportunity Management: NetSuite’s CRM allows manufacturing companies to track leads and opportunities, helping them manage the sales pipeline, forecast revenue, and prioritise sales efforts.

- Customer Interaction Tracking: The CRM module enables manufacturers to keep a record of customer interactions, emails, meetings, and communications. This centralised information can help teams provide personalised service and support.

- Sales Forecasting: Manufacturers can use NetSuite’s CRM to analyse historical sales data and project future sales trends, aiding in production planning and resource allocation.

- Customer Support: The CRM module includes customer support features that can assist manufacturers in managing customer inquiries, issues, and service requests.

- Customisation: NetSuite’s CRM can be customised to align with the specific needs of a manufacturing business. This allows companies to adapt the CRM functionalities to their unique sales and customer service processes.

- Integration with ERP: One of NetSuite’s strengths is its seamless integration between CRM and ERP functionalities. This integration enables manufacturers to have a holistic view of customer interactions, orders, production, and financials.

It’s important to note that while NetSuite’s CRM capabilities can certainly benefit manufacturing companies, the CRM component is just one part of the broader NetSuite ERP solution. Manufacturing companies that choose NetSuite can leverage both the CRM and ERP functionalities to manage their entire business operations, from customer interactions to production processes and supply chain management. At AVT, Australia’s Leading NetSuite Solution Provider, we’re committed to helping Manufacturing businesses harness NetSuite’s full potential to drive growth, efficiency, and success in a highly competitive market.

How Successful NetSuite Software is in the Manufacturing Industry?

NetSuite has demonstrated significant success in serving the manufacturing industry with its ERP (Enterprise Resource Planning) software tailored for manufacturing companies. Its success can be attributed to a combination of its robust features, industry-specific capabilities, and the ability to address the unique challenges faced by manufacturing businesses.

Here are some reasons why NetSuite software has been successful in the manufacturing industry:

- Industry-Specific Functionality: NetSuite offers a Manufacturing Edition with features designed specifically for manufacturing processes. This includes tools for production planning, inventory management, quality control, shop floor management, and more, addressing the distinct needs of manufacturers.

- End-to-End Integration: NetSuite integrates various aspects of manufacturing operations, from production and inventory to supply chain management and financials. This integration eliminates data silos, enhances visibility, and facilitates collaboration across departments.

- Real-Time Insights: NetSuite provides real-time data and analytics, empowering manufacturers to make informed decisions. This helps in optimising production processes, resource allocation, and demand forecasting.

- Shop Floor Control: NetSuite’s shop floor control features enable manufacturers to monitor and manage production activities in real time. This enhances production efficiency and allows quick response to changes on the shop floor.

- Supply Chain Optimisation: NetSuite facilitates supply chain optimisation by integrating suppliers, distributors, and logistics partners. This streamlines procurement, reduces lead times, and improves overall supply chain efficiency.

- Quality Control: With quality management tools, NetSuite supports manufacturers in maintaining product quality and meeting industry regulations. It enables inspections, non-conformance tracking, and quality assurance.

- Customisation: NetSuite allows manufacturers to customise workflows, forms, and processes to align with their specific requirements. This flexibility ensures that the software adapts to the unique needs of each manufacturing business.

- Scalability: NetSuite’s scalability makes it suitable for both small manufacturers and large enterprises. It can grow alongside the business and accommodate changing production volumes.

- Cloud-Based Solution: Being a cloud-based solution, NetSuite offers accessibility from anywhere, seamless updates, and reduced IT infrastructure costs—a valuable advantage for manufacturers with multiple locations or remote teams.

- Industry Expertise: NetSuite has a proven track record of serving manufacturing companies across various industries, including discrete manufacturing, process manufacturing, electronics, automotive, and more.

NetSuite’s success in the manufacturing industry is further strengthened by its ability to support businesses in optimising processes, enhancing customer relationships, and driving growth. As with any software, the success of its implementation depends on various factors, including proper planning, customisation, and ongoing support. Working with AVT – Australia’s Leading NetSuite Solution Provider & Partner, our experienced NetSuite Consultants and NetSuite Support Services Team can ensure that manufacturing companies extract the maximum benefits from the software to achieve their operational and strategic goals.

What is the best software for Manufacturing companies?

NetSuite is widely recognised as a top choice for manufacturing companies due to its strengths in providing a comprehensive solution tailored for the industry’s needs.

Its benefits include:

- Industry-Specific Features: NetSuite offers a Manufacturing Edition with features designed to streamline production planning, shop floor control, inventory management, and more.

- End-to-End Integration: NetSuite seamlessly integrates manufacturing operations with financials, supply chain, and customer management, providing a unified view.

- Real-Time Visibility: NetSuite offers real-time insights into key performance indicators, enabling informed decisions and quick responses to market changes.

- Quality Management: NetSuite supports quality control through tools for defining standards, inspections, and non-conformance management.

- Supply Chain Optimisation: NetSuite enhances supply chain efficiency by integrating suppliers, distributors, and logistics partners.

- Scalability: NetSuite is scalable to accommodate growth, making it suitable for both small and large manufacturing businesses.

- Cloud-Based Advantage: As a cloud-based solution, NetSuite offers accessibility, updates, and reduced IT costs for multi-location businesses.

- Proven Expertise: NetSuite’s success in serving various manufacturing sectors, from discrete to process manufacturing, demonstrates its industry expertise.

Overall, NetSuite’s tailored features, seamless integration, and industry expertise make it an exceptional choice for manufacturing companies seeking to optimise operations, enhance quality, and drive growth. As Australia’s leading NetSuite Solution Provider, AVT is committed to helping Manufacturing companies harness the full potential of NetSuite to drive growth and success. With our expertise and tailored solutions, we empower businesses to optimise their operations, enhance customer experiences, and thrive in a competitive market.

Is ERP software the best for a Manufacturing start up?

Yes, ERP software is an excellent choice for a manufacturing startup, and NetSuite stands out as a prime solution.

NetSuite’s strengths make it ideal for manufacturing startups due to:

- Tailored Manufacturing Edition: NetSuite offers a specialised Manufacturing Edition with features designed to meet the unique needs of manufacturing startups.

- End-to-End Integration: NetSuite seamlessly connects manufacturing processes with financials, supply chain, and customer management, ensuring streamlined operations.

- Real-Time Insights: NetSuite provides real-time visibility into critical manufacturing metrics, empowering startups to make informed decisions from day one.

- Scalability: NetSuite grows with your startup, accommodating increased production volumes and complexity as your manufacturing business expands.

- Cloud-Based Flexibility: Being cloud-based, NetSuite offers accessible and scalable solutions without the need for heavy IT infrastructure investment.

- Industry Expertise: NetSuite’s proven success in serving manufacturing industries demonstrates its ability to cater to startup needs effectively.

In summary, NetSuite’s tailored features, integration capabilities, real-time insights, and scalability make it an optimal choice for manufacturing startups seeking efficient and growth-focused ERP solutions. As Australia’s leading NetSuite Solution Provider, AVT can guide you through the entire process, from selecting the right ERP solution to implementation and ongoing support, ensuring that your startup thrives in a competitive market environment.

What is NetSuite Advanced Manufacturing Edition?

NetSuite Advanced Manufacturing Edition is a specialised offering within the NetSuite ERP (Enterprise Resource Planning) suite, designed to address the complex needs of manufacturing companies. This edition extends the capabilities of standard NetSuite ERP with advanced features specifically tailored to meet the challenges faced by manufacturers across various industries. The goal of NetSuite Advanced Manufacturing Edition is to optimise production processes, enhance supply chain management, and provide real-time insights to drive operational excellence.

Key features and benefits of NetSuite Advanced Manufacturing Edition include:

- Production Planning and Scheduling: This feature enables manufacturers to plan and schedule production activities efficiently, ensuring optimal resource utilisation and on-time delivery.

- Shop Floor Control: Manufacturers can monitor and manage shop floor operations in real time, tracking production progress and identifying areas for improvement.

- Work Order Management: NetSuite Advanced Manufacturing Edition supports work order creation, tracking, and management, providing visibility into the status of each order.

- Material Requirements Planning (MRP): MRP tools assist in managing inventory levels by forecasting demand and automating reorder processes, preventing stock-outs or overstock situations.

- Quality Control and Compliance: The edition offers tools to define and enforce quality standards, manage inspections, and ensure compliance with industry regulations.

- Demand Forecasting: Manufacturers can use advanced forecasting tools to predict demand patterns accurately, enabling efficient resource allocation and production planning.

- Supply Chain Optimisation: The solution supports end-to-end supply chain management, from procurement to distribution, enhancing collaboration with suppliers and distributors.

- Real-Time Analytics: NetSuite’s Advanced Manufacturing Edition provides real-time insights into production performance, inventory levels, and other critical metrics, aiding informed decision-making.

- Configurable Workflows: Manufacturers can customise workflows to align with their unique processes, ensuring the software adapts to specific business requirements.

- Industry-Specific Functionality: NetSuite Advanced Manufacturing Edition caters to various manufacturing types, including discrete, process, and mixed-mode manufacturing.

By offering these specialised features, NetSuite Advanced Manufacturing Edition empowers manufacturers to optimise processes, improve product quality, and respond effectively to market demands. It’s a solution tailored to support manufacturing businesses in achieving operational efficiency and success within a competitive industry landscape. If you’re considering using NetSuite Advanced Manufacturing Edition for your business, contact AVT – Australia’s Leading NetSuite Solution Provider & Partner for the most up-to-date and detailed information about the features and benefits.

What features does NetSuite Advanced Manufacturing offer?

NetSuite Advanced Manufacturing offers a comprehensive suite of features designed to meet the intricate needs of manufacturing companies. These features are tailored to optimise production processes, enhance supply chain management, and provide real-time insights to drive operational excellence.

Here are the key features that NetSuite Advanced Manufacturing Edition offers:

- Production Planning and Scheduling: Efficiently plan and schedule production activities, ensuring optimal utilisation of resources and on-time delivery.

- Shop Floor Control: Monitor and manage shop floor operations in real time, tracking production progress and identifying opportunities for improvement.

- Work Order Management: Create, track, and manage work orders, providing visibility into the status of each order and facilitating efficient production execution.

- Material Requirements Planning (MRP): Automate inventory replenishment by forecasting demand and managing materials to prevent stock-outs and overstock situations.

- Quality Control and Compliance: Define quality standards, manage inspections, and ensure compliance with industry regulations to maintain product quality.

- Demand Forecasting: Accurately predict demand patterns using advanced forecasting tools, enabling effective resource allocation and production planning.

- Supply Chain Optimisation: Manage end-to-end supply chain processes, from procurement to distribution, improving collaboration with suppliers and distributors.

- Real-Time Analytics: Access real-time insights into production performance, inventory levels, and key metrics for informed decision-making.

- Configurable Workflows: Customise workflows to match unique manufacturing processes, ensuring the software adapts seamlessly to specific business requirements.

- Advanced Costing: Gain a deep understanding of production costs by analysing materials, labor, and overhead expenses at a granular level.

- Lot and Serial Number Tracking: Trace products through the supply chain with lot and serial number tracking, ensuring compliance and enabling quality control.

- Engineering Change Control: Manage engineering changes, ensuring smooth transitions while maintaining product integrity and avoiding disruptions.

- Multi-Site and Multi-Location: Manage manufacturing operations across multiple sites and locations, providing visibility and control over dispersed operations.

- Integrated Financials: Seamlessly integrate manufacturing operations with financial processes for accurate cost tracking and financial reporting.

NetSuite Advanced Manufacturing Edition’s robust feature set empowers manufacturers to streamline operations, enhance product quality, and respond effectively to market demands. By addressing the unique challenges of manufacturing, this solution supports businesses in achieving operational efficiency and success within a competitive industry landscape. For the most up-to-date and detailed information about the features and capabilities of NetSuite Advanced Manufacturing Edition, contact AVT – Australia’s Leading NetSuite Solution Provider & Partner to assist you in evaluating how NetSuite can meet the specific needs of your Manufacturing business.

What types of companies can use NetSuite Advanced Manufacturing?

NetSuite Advanced Manufacturing is designed to cater to a wide range of manufacturing companies across different industries. Its versatile features and capabilities make it suitable for various types of manufacturers, including:

- Discrete Manufacturers: Companies that produce distinct, separate items—such as electronics, machinery, automobiles, and consumer goods—can benefit from Advanced Manufacturing Edition’s production planning, quality control, and supply chain optimisation.

- Process Manufacturers: Businesses involved in producing goods through chemical reactions, mixing, or assembly processes, like food and beverage, pharmaceuticals, and chemicals, can utilise the edition’s features to manage complex manufacturing workflows.

- Mixed-Mode Manufacturers: Companies that combine elements of both discrete and process manufacturing, such as those in the aerospace or automotive industries, can leverage the edition’s versatility to manage diverse production processes.

- High-Tech Manufacturers: Organisations in the technology sector, including electronics and semiconductor manufacturing, can utilise the edition’s advanced capabilities to manage complex production and demand variations.

- Industrial Manufacturers: Companies that produce machinery, equipment, and industrial goods can benefit from features like shop floor control, demand forecasting, and supply chain optimisation.

- Consumer Goods Manufacturers: Businesses producing consumer products, including apparel, home goods, and packaged goods, can optimise their production processes and supply chain using the edition’s tools.

- Automotive Manufacturers: Automotive companies can manage intricate production schedules, optimise supply chain operations, and ensure high-quality output with Advanced Manufacturing Edition.

- Aerospace and Defence Manufacturers: Organisations in this sector can benefit from the edition’s capabilities in managing complex assemblies, stringent quality control, and compliance requirements.

- Medical Device Manufacturers: Businesses in the medical device industry can use the edition’s features to manage production of intricate and regulated products while maintaining compliance.

- Electronics Manufacturers: Electronics manufacturing companies can streamline their processes, manage components, and forecast demand using the edition’s specialised tools.

In essence, NetSuite Advanced Manufacturing Edition caters to a diverse spectrum of manufacturing industries, each with unique production processes and challenges. Its versatility and industry-specific functionalities enable companies to optimise operations, enhance quality, and achieve operational excellence within their respective manufacturing sectors.

Can NetSuite Manufacturing be customised to fit our specific business needs?

Yes, NetSuite Manufacturing can be customised to align with the specific needs and processes of your business. One of NetSuite’s strengths is its flexibility, which allows manufacturers to tailor the software to match their unique requirements. This customisation ensures that the solution adapts seamlessly to your manufacturing operations.

Here’s how NetSuite Manufacturing Edition can be customised:

- Workflow Customisation: You can configure workflows to match your manufacturing processes, from production planning to quality control. This ensures that the software mirrors your business operations.

- Data Fields and Forms: Customise data fields and forms to capture relevant information specific to your manufacturing needs. This enables accurate data recording and reporting.

- Reporting and Analytics: Create customised reports and dashboards to track key performance indicators (KPIs) that are crucial to your manufacturing processes.

- Integrations: Integrate NetSuite Manufacturing Edition with other systems or applications your business uses, ensuring seamless data flow and reducing manual data entry.

- User Interface: Tailor the user interface to present information and functionalities relevant to different user roles within your manufacturing operations.

- Add-Ons and Extensions: NetSuite’s SuiteCloud platform offers add-ons and extensions that can further enhance the functionality of Manufacturing Edition, addressing specific needs.

- Mobile Access: Customise mobile interfaces to enable your team to access critical manufacturing information on the go.

- Compliance and Regulations: Customise processes and data fields to meet industry-specific compliance requirements and regulations.

NetSuite’s flexibility in customisation ensures that Manufacturing Edition adapts to your unique business model, processes, and industry standards. It’s important to note that while NetSuite offers extensive customisation capabilities, it’s recommended to work with experienced NetSuite Solution Providers like AVT – Australia’s Leading NetSuite Solution Provider & Partner to ensure that customisations are implemented effectively and efficiently. Contact AVT to help analyse your business processes, understand your unique needs, and guide you through the customisation process to ensure that NetSuite Advanced Manufacturing Edition aligns perfectly with your specific business requirements.

How does NetSuite Manufacturing handle inventory management?

NetSuite Manufacturing Edition offers robust inventory management capabilities designed to streamline manufacturing operations, optimise resource utilisation, and maintain optimal inventory levels.

Here’s how NetSuite Manufacturing handles inventory management:

- Real-Time Visibility: NetSuite provides real-time visibility into inventory levels across multiple locations, helping manufacturers make informed decisions and preventing stock-outs or overstock situations.

- Demand Forecasting: The solution assists in predicting demand patterns based on historical data and market trends. This helps optimise inventory levels and align production with customer needs.

- Material Requirements Planning (MRP): NetSuite’s MRP tools calculate the materials needed for production based on demand forecasts, existing inventory, and production schedules. This prevents material shortages and production disruptions.

- Purchase Order Management: Manufacturers can generate purchase orders directly from MRP recommendations, ensuring timely procurement of materials and components.

- Lot and Serial Number Tracking: NetSuite allows tracking of products by lot or serial numbers throughout the manufacturing and distribution process. This feature is crucial for industries with regulatory requirements or complex supply chains.

- Just-In-Time Inventory: Manufacturers can implement Just-In-Time inventory practices to minimise storage costs and reduce excess inventory, improving cash flow.

- Reorder Point Management: NetSuite helps define reorder points for items, automatically triggering reorder processes when inventory falls below a specified level.

- Multi-Site Management: For manufacturers with multiple locations, NetSuite enables central management of inventory across sites, ensuring consistency and accuracy.

- Quality Control Integration: Inventory management is integrated with quality control processes, ensuring that materials meet quality standards before being used in production.

- Barcode Scanning: NetSuite supports barcode scanning for efficient inventory tracking, reducing manual data entry errors.

- Bin Management: Manufacturers can define bin locations for inventory storage, optimising warehouse layout and ensuring efficient picking and stocking.

- FIFO/LIFO Management: NetSuite enables manufacturers to manage inventory using First-In-First-Out (FIFO) or Last-In-First-Out (LIFO) methods, aligning with accounting practices.

- Cycle Counting: NetSuite facilitates periodic cycle counting to ensure inventory accuracy, minimising discrepancies and ensuring optimal stock levels.

In essence, NetSuite Manufacturing Edition’s inventory management capabilities provide manufacturers with the tools they need to optimise materials, minimise costs, and enhance overall supply chain efficiency. By offering real-time insights, demand forecasting, and integration with other manufacturing processes, NetSuite supports manufacturers in maintaining optimal inventory levels while ensuring smooth production operations.

Request Solution Demo

Fill the Form Below to Get Started on your Digital Transformation

Our Oracle NetSuite for Manufacturing Companies Form will help you to price/budget your NetSuite ERP Software investment. Please note that the estimate is provided on best estimate basis and any discounts/offers are negotiated additionally. The estimates are indicative only and formal commercial estimate is issues once your account is verified and engagement established. AVT ERP Sales and Solutions representative will get in touch with you to confirm your details before any estimate is formally issued. Please make sure your email and phone numbers are correct so we can reach to verify your account. Any feedback or questions please don’t hesitate to email us on sales@abvt.com.au