Supply Allocation in NetSuite – AVT Tips and Tricks

Supply Allocation in NetSuite

AVT Tips and Tricks

In attempting to optimise the amount of inventory being held, businesses are involved in a risk assessment along the lines “how much of an Item should we carry to minimise the likelihood of not delivering to a customer when the customer wants it.” it essentially the capital cost of holding the extra inventory versus the cost of a lost sale and its impact on customer loyalty.

Most systems commit available inventory to sales orders at the time of the order when the order is received. This produces a number of disadvantageous scenarios:

- An unexpected and large order consumes the bulk of available inventory and lead time means replenishment lead time will mean a period of time of stock out.

- Low available inventory may be consumed by occasional customers while regular, larger purchasing customers are left without products.

- On Order, incoming inventory may be visible to order entry operators but cannot be committed creating the risk that this receipt may be overcommitted by enthusiastic sales people.

In these situations the typical resort is to try to reallocate orders through a manual intervention where a senior salesperson may remove allocations from some orders and apply the stock to another.

This may resolve the overall inventory situation but only at the cost of the time taken to do the reallocation and that taken to apologise to the clients who suddenly find out that they are not getting the inventory that they had been expecting.

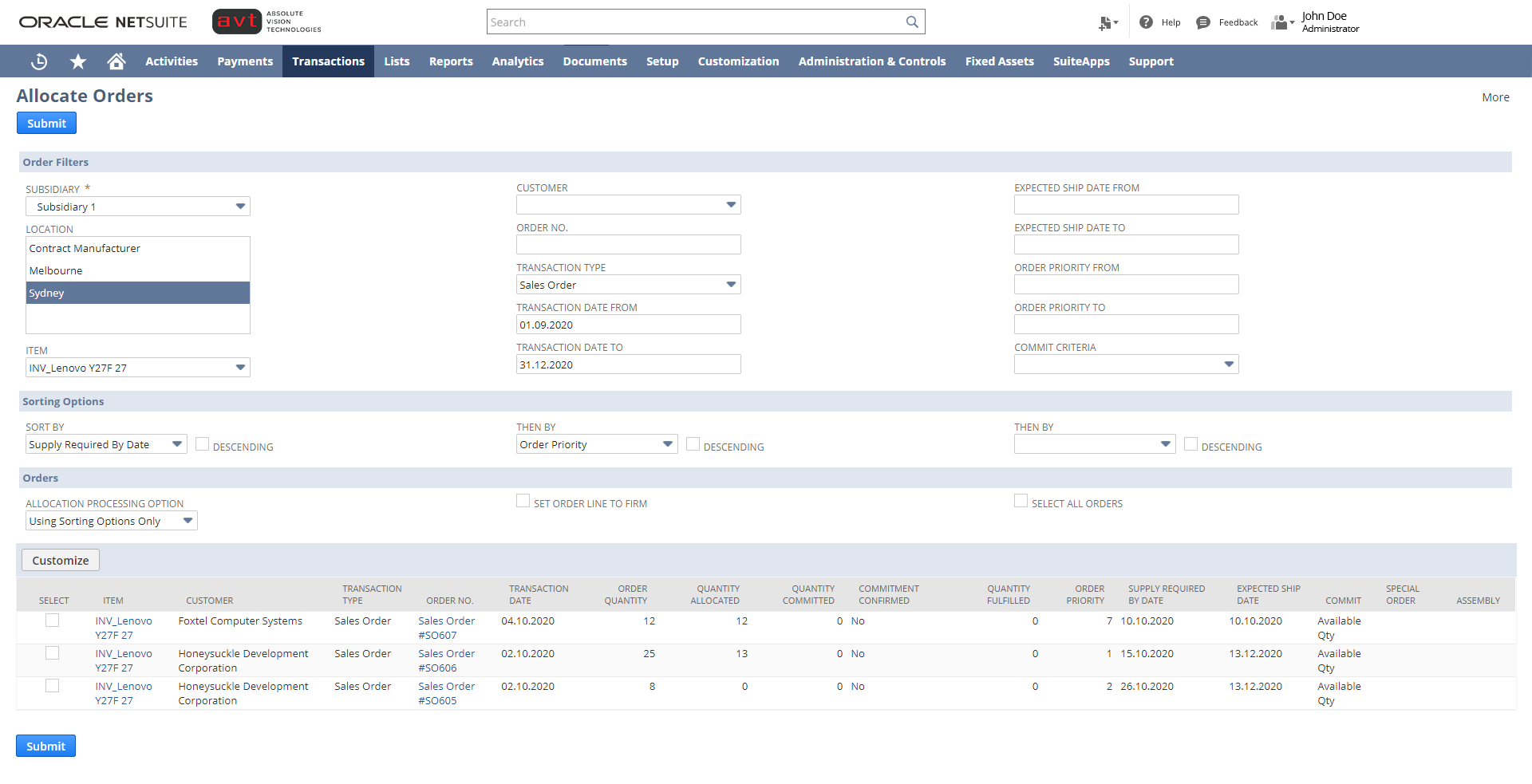

NetSuite’s Supply Allocation functionality is a boon to organisations routinely experiencing any of the the above and particularly those with key items that are imported.

Key Points are:

- When demand orders such as sales or transfers are entered, the allocation engine also considers planned inventory orders, such as purchase orders, transfer orders and work orders, to match supply with demand based on the date that supply is required.

- When Supply Allocation matches demand orders that have future ship dates to supply orders with future receipt dates, on-hand inventory remains available to fill immediate demand orders.

- If multiple orders are changed and a large amount of inventory is removed, the setting determines which orders are affected and which orders get items allocated first.

- Quantities will be de-committed based on the quantity being reduced on the transaction with a committed quantity and the oldest transaction date.

The functionality will typically be triggered as the order is created but NetSuite provides for both manual and scheduled batch processes which can be run at specific times through the day (permit in line with picking processes).

These strategies can be based on criteria such as location, customer ranking, order priority and more.

If inventory allocation to sales is causing major headaches for your organisation then this is definitely worth investigation.

If you have any questions about the upcoming New Release or would like help preparing your organisation for the transition, please contact us at support@abvt.com.au.

Please also consider book-marking the AVT Support Services – your go-to resource to submit support tickets and access knowledge base articles. The AVT Support Services also contains a direct link to NetSuite’s system status page.

Kind regards,

AVT Business Solutions

Need more info?

Find out more at the NetSuite Blog page